Ottobock and Waterjet share a vision

Ottobock is a German multinational company that has been in business for almost a century and has more than 7,000 employees in more than 140 countries worldwide where it operates in. Founded in Germany by Otto Bock in 1919, the company is a leader in the world of orthopaedic and rehabilitation technology and produces prosthetic devices, corsets, orthotics, wheelchairs for children and cushions and accessories featuring very high quality standards and advanced technology. At the origin of Ottobock’s success lies the vision of its founder who, in contrast to the other prosthetic manufacturers, instead of starting from wood and working it to reach the most suitable prosthetic morphology, industrialised the production of the various components, creating a unique and personalised limb for each patient by being combined, modified or adapted.

For this prestigious job order, Waterjet Corporation followed Ottobock’s approach, starting f rom a machine with a history of industrialised production, modifying and customising it according to the client’s needs.

“Our strength,” says Massimo Russo “was the customisation of the multiple 3D cutting system based on the application specifications of the client’s production. The machine core structure – interpolating Cartesian axes, transmission mechanics and handling precision – is generated at an industrial level, in line with the high precision and reliability standards of Waterjet Corporation. Customisation is aimed at providing the best possible cutting performance: this responsiveness generates trust. There were four other suppliers competing: Waterjet won because it was able provide the ad-hoc technological solution for the client’s application”.

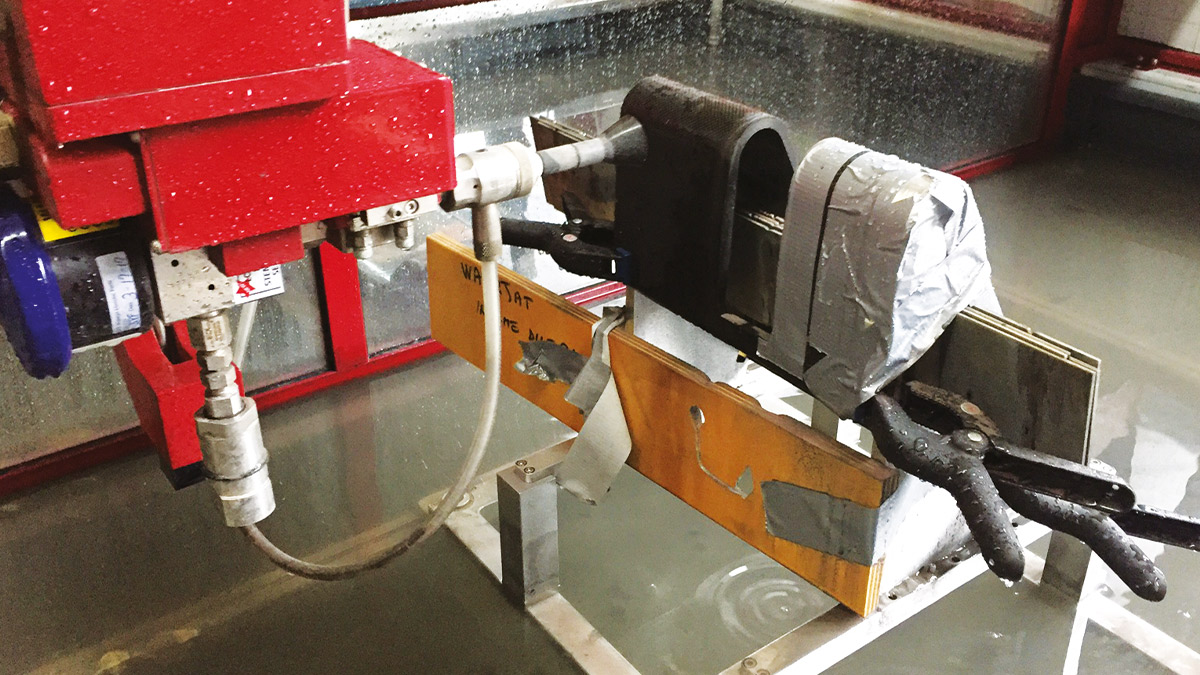

Waterjet sold and installed a highly customised Supreme DX 612 in the Ottobock production centre in Salt Lake City, Utah, in the US.

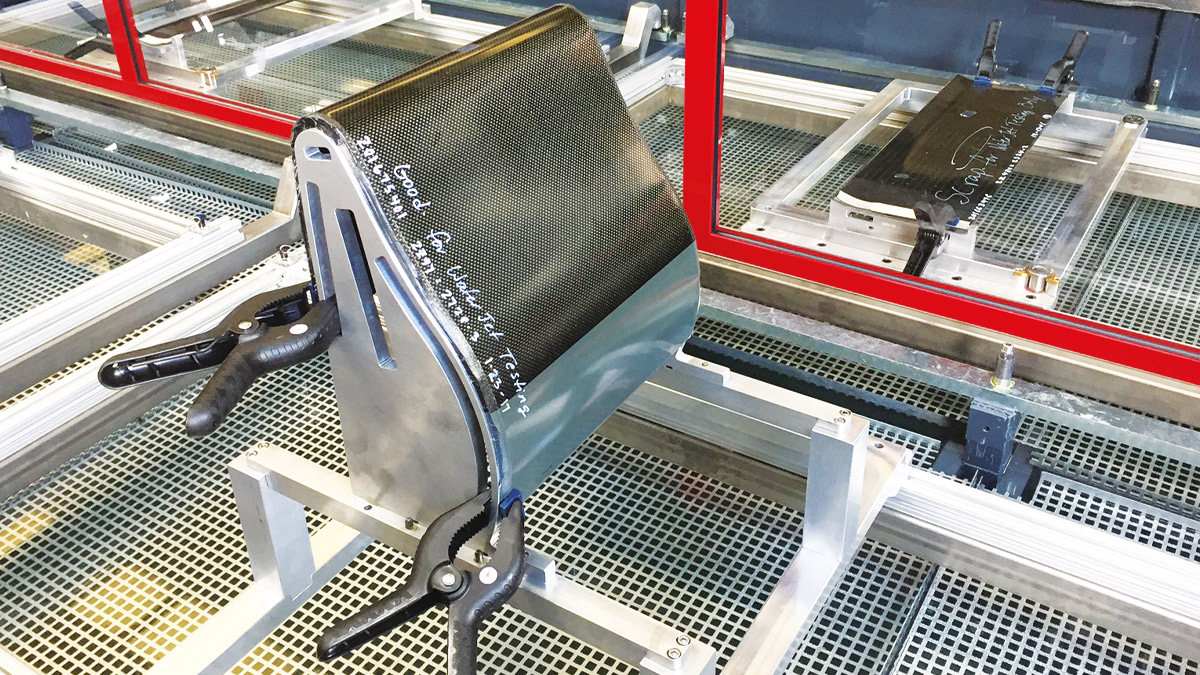

Namely, the high degree of customisation consists in:

- Worktop divided into four areas – two at the front and two at the back;

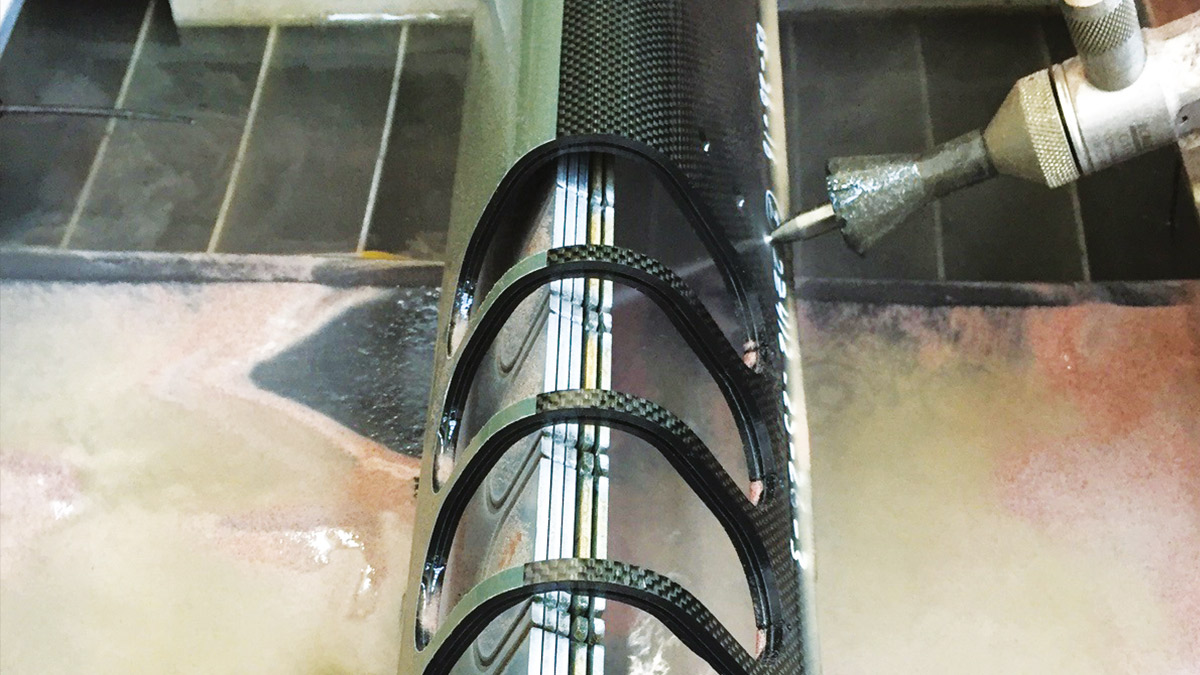

- 5-axis cutting head with ±90° cutting angle for horizontal cutting;

- Cutting head with optional drill for pre-drilling;

- Camera for automatic recognition of the entire work process;

The camera reads barcodes and verifies whether the template where the customised means is placed on to cut the piece is correct, whether it is positioned in the correct working area and whether the cutting support coincides with the piece: once the suitability of all these parameters is verified, it launches a preset program that guides the cutting head. The percentage of human error is therefore reduced to zero.

The cutting phase can entail the optional use of the drill for pre-drilling: the preliminary processing prevents any chance of delaminating the piece. Despite water jet technology being a cold processing method that protects the physical and chemical properties of the material, when this technology is used to drill multi-layered material, it can generate a reflex force that delaminates the integrity of the piece, thereby creating bubbles between one sheet and another. Pre-drilling creates a starting hole where the jet is inserted and, this way, it will not exert vertical compression, but only a lateral cutting action.

The software with which the machine is equipped automatically interfaces with the IT system of the company, generating a continuous flow of information to optimise production in real time: working in this automatic way, the Salt Lake City facility has significantly increased the water cutting cycle productivity by 400%.

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires