Eurofoam

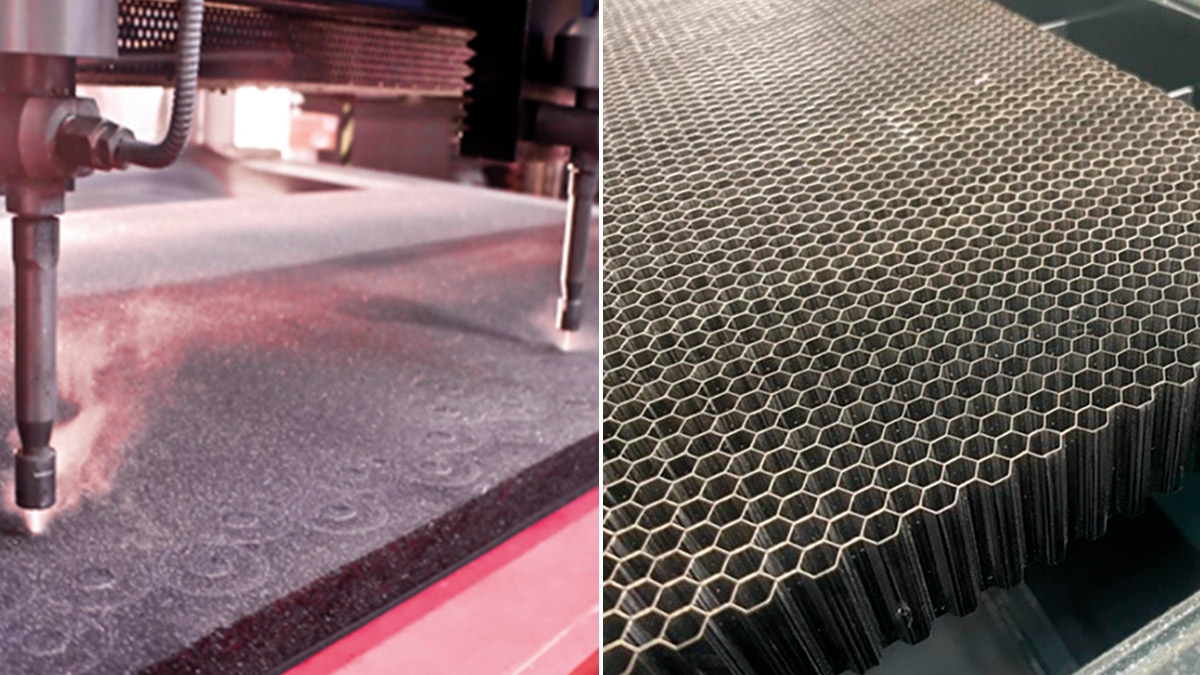

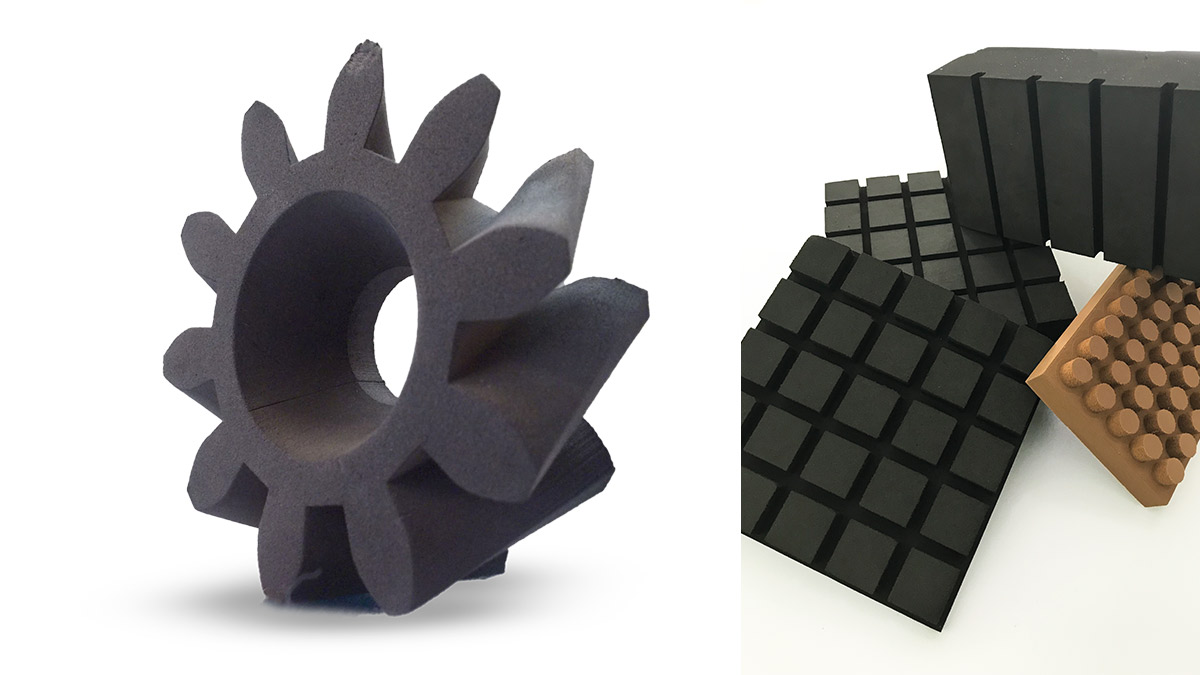

Eurofoam is a company that since 1965 has been producing technical articles from raw materials in compact rubber foam, either tailor-made or mass produced for a vast range of highly complex industrial applications. Eurofoam has extensive experience in waterjet cutting: “we installed the first machine for waterjet cutting at the beginning of the 1990s.

We have been using this technology for thirty years, which is fundamental for companies like us working with ultra-thick foam materials. But now that the competition in this sector is very fierce, we needed a technology partner, rather than a supplier to compete in the market. Which is why we chose Waterjet Corporation”, says Gianpaolo Sandrini, CEO of Eurofoam, about his relationship with Waterjet.

The machine is a Classica model with the bridge on the short side only, customised to meet the customer’s production requirements:

- 2 independent work areas with a pendulum system for optimised loading and unloading of materials;

- telescopic heads for access to the greatest possible cutting geometry;

- 2 Servo hybrid pumps in parallel for maximum flow management of pressure and high energy savings.

These aspects converge to generate ultra-high productivity, optimised further by compliance of the machine with Industry 4.0: the machine is connected to the company’s network for the real-time transmission and storageof information, thus falling under the capital goods included in the Industry 4.0 plan.

The system is, in fact, controlled remotely by the production technicians: “the machine works continuously on two work shifts”, says Pietro Orbelli, head of Eurofoam production, “when you manufacture for such long working hours – bear in mind that the machine has been operating for three months and has already clocked up 500 working hours – it is fundamental to be able to optimise production by adjusting different production parameters to manage consumption and plan production.

The option of managing the machine remotely also becomes highly important with a view to anticipating unscheduled maintenance work.

Being able to continuously monitor all the technical parameters of the machine means we can see in advance where there will be a need to intervene and thus anticipate maintenance scheduling”.

A large part of the successful bid is down to maintenance: Eurofoam was looking for a partner that could provide not only high-performance technology but also a skilled and efficient service to manage routine and unscheduled maintenance work.

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires