Dr. Greiche Glass

Water-jet cutting technology is able to provide a concrete advantage over other cutting or drilling technologies whenever high precision is required and the chemical-physical characteristics of the glass must be protected. The technology can be applied to glass of any thickness: water-jet cutting is a cold technology and makes a soft, precise, separation cut, in a clean and clear way.

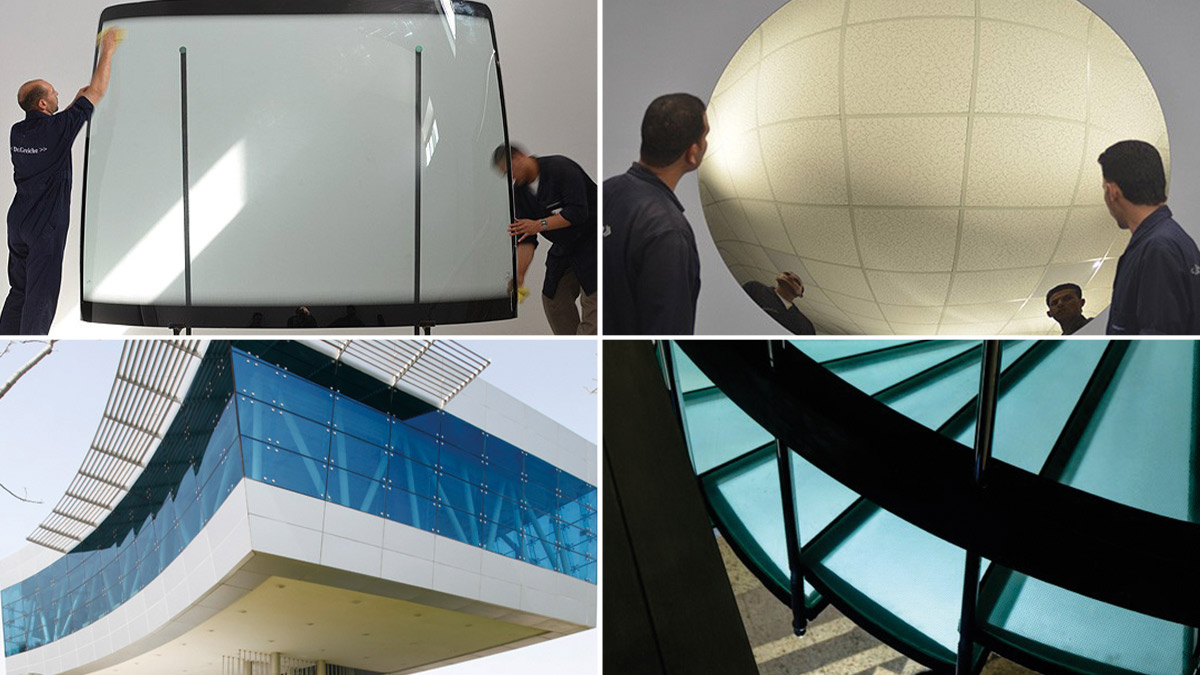

Dr. Greiche, leading player in the second glass processing industry in the Middle East and Africa, provides quality glass solutions to the automotive, architectural, decorative and home appliance sectors. It is a company that currently employs more than 1,650 operators in its factories where the best glass processing technologies are available. Water-jet cutting technology is part of these several production facilities: Waterjet Corporation machines have been elected by the key Egyptian player to represent this category.

The productive advantage that Water-jet machines are called upon to deliver is that of making precise cuts and drilling, even of extremely small dimensions, on tempered glass plates: where numerical control cutting via tool, for obvious reasons, is not viable, water jet technology assures precision and high productivity. The holes and cuts made with Waterjet machines are crucial for the result of the subsequent tempering glass stages which, if activated on chipped slabs, would stiffen and worsen the defect, rendering the slabs unusable with consequent negative effects on production.

As on other occasions, the key element for the Egyptian customer order was loyalty: the decision to purchase two new Waterjet Corporation machines by Dr. Greiche came five years after the first purchase. The customer therefore, satisfied with the product and service, confirmed the supplier and doubled the stakes.

For this order, Waterjet Corporation sold two machines to the customer. A Pratica model with a cantilever bridge that facilitates loading/unloading operations. The machine is in fact equipped with a tilting work table which can reach up to 89° thanks to an electric motor and therefore can easily load large glass sheets. The table is raised and lowered in less than 60 seconds, minimising loading/unloading times. The reduced loading/ unloading time, paired with the processing speed provided by the water technology, provide the high productivity required by the customer company and that they appreciate day after day. Large numbers are a crucial strategic advantage for being competitive in the architecture and home appliance sectors.

Along with Pratica, Waterjet also sold a simpler model: a Prima with a cantilevered bridge and a 3.4 x 1.6m 3-axis worktop, used by the customer to manufacture induction tops, mirrors, and other furnishing accessories.

“For us at Waterjet, the loyalty of high-level customers such as Dr. Greiche is a source of great satisfaction: when such an important customer renews their trust in us, it is a source of great gratification for me, that I personally followed the sale, and for all the operators who contributed every day to the success of Waterjet Corporation” comments Eng. Massimo Russo, owner of Waterjet Corporation srl.

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires