Pegasus S.r.l.

Pegasus is an industrial company from Piedmont which operates in the production of components mainly intended for the Oil & Gas and heavy mechanical engineering sectors. The Oil & Gas sector in particular, is regulated on a global scale by strict quality and safety control protocols to protect the ecosystems in which the plants are installed: every piece that leaves production must necessarily pass very strict quality control processes.

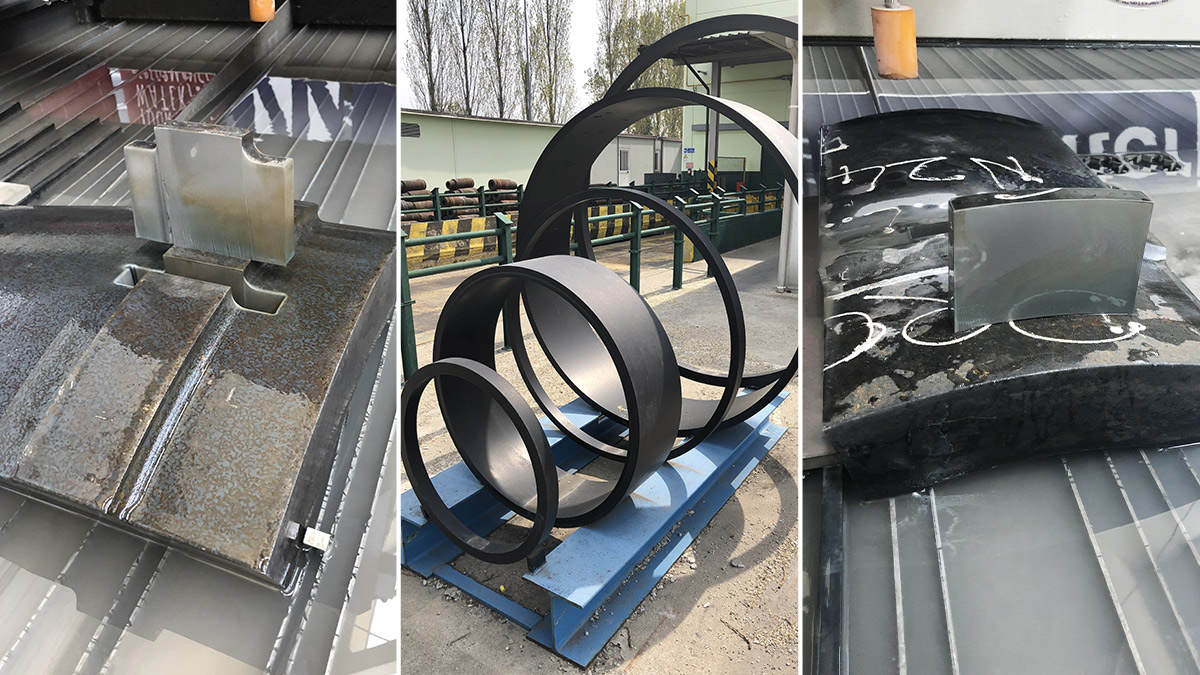

In particular, for realising the “specimens”, the samples of the material obtained from the components produced, Pegasus turned to Waterjet, requesting a machine capable of cold cutting portions of steel from the enormous valves manufactured. An out and out “core drilling”, the extraction of material to verify the quality of the product core.

Before Waterjet, Pegasus carried out these samples on the pieces produced by using other technologies which required more time to complete the specimen. With water cutting, no second processing is necessary to achieve excellent finishing levels.

In addition to time-related issues, it was also necessary to have a technology for cold cutting as, given that it is a separation cut, the chemical-physical characteristics of the material remain unaltered and the sample obtained proves to be irrefutable proof of the overall quality of the material with which the component is made. Indeed, the Waterjet cut guarantees the absence of thermally altered areas.

Waterjet supplied Pegasus with a Classica CL 56 with a 2,000 x 1,500 mm work surface: a particularity of this order lies in the customisation of the work area, whose height was increased to 1,100 mm to facilitate the housing of these enormous valves with a bridge crane and therefore to carry out the cut, including transversal, completely safely. In collaboration with the customer, the Waterjet technicians designed an anchoring system on the bottom of the valves which therefore are “welded” onto the work surface.

Obviously, the cutting support technology which the machine is equipped with is at the top of the range: the pump for the intensification of the jet is at 6,000 bar to enable working large thicknesses.

The 5-axis machine has a cutting angle between ± 69°: the cutting head, in fact, must be able to follow the curvature of the piece to make transverse, axial and lateral cuts.

The data from the first tests were excellent and immediately reassured Pegasus, which ascertained the ability of the Waterjet Corporation to safeguard the productivity of client companies.

The material on which the tests were carried out is a rolled steel with a 300 HB hardness. The cutting speed achieved by the machine on a thickness of 84 mm was 28.5 mm/minute for a total machining time of approximately 14 minutes. These are incontrovertible data of the performance that the Waterjet machines can guarantee.

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires