Oil & Gas Carrara

Carrara Spa, one of Europe’s leading manufacturers of industrial gaskets, is a company that focuses on high production quality and, for this reason, has

always been equipped with production systems capable of achieving high quality standards.

Waterjet cutting systems had already been part of the Carrara equipment for some time. In July 2021, the company decided to purchase a new machine for a specific cutting application of large-scale, extra-thick semi-machined stainless steel rings.

“We organised a series of meetings with the customer to understand the real requirements needed by the specific application for which the machine was intended. By listening carefully to the needs combined with our product cus- tomisation expertise, we were able to develop and customise a machine with unique features in terms of structure and size which was suited to the customer’s requirements”, says Daniele Portoso, Head of Sales in Italy who personally over- saw the sale.

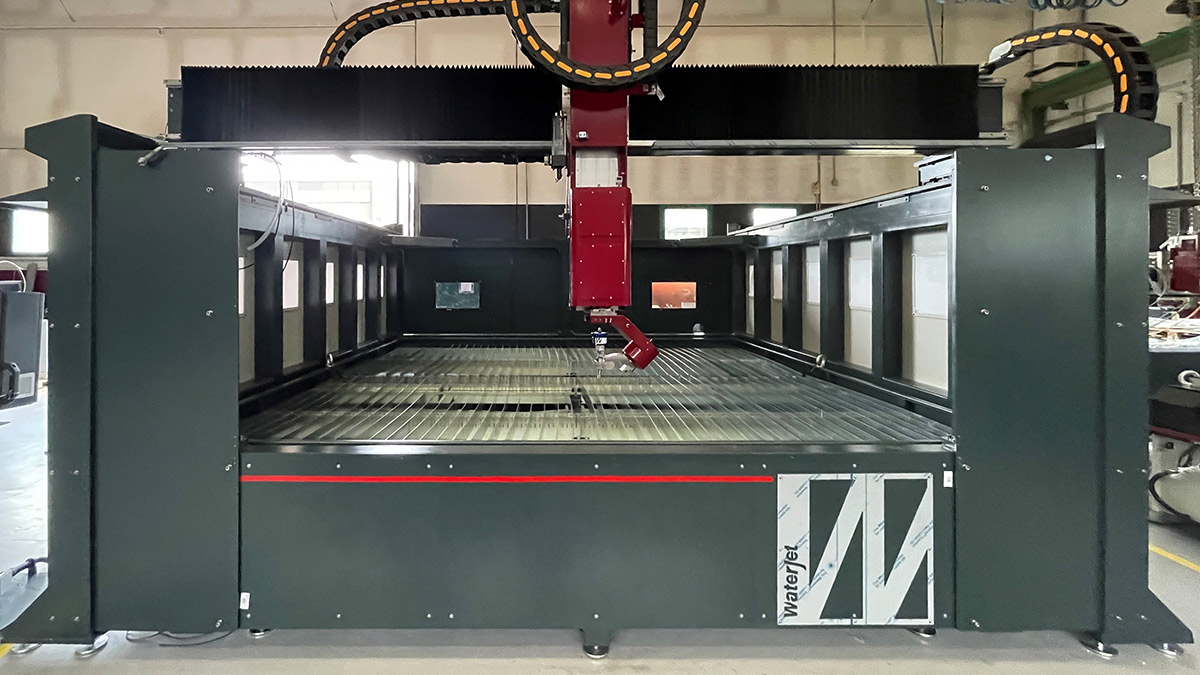

Numerous tests were completed with the customer to assess the ideal tooling and configuration to meet the real require- ments: the solution was a Classica CLT model with a work area measuring 3000 mm x 3000 mm completely enclosed in a cabin with an automated tilting front panel for positioning the workpieces with an overhead crane.

The rear and side partitions are designed to support the bridge which houses the 3D cutting head with a ± 90° inclination with 1200 mm Z axes.

The semi-machined rings, to be cut with water jets, are handled by the overhead crane which positions the workpiece on the work surface. The safety system does not allow cutting to start until the front door is completely closed to that the operator is safety out of harm’s way. The machine’s large-scale housing also helps to keep noise down and the working en- vironment clean.

Numerous customer audits took an in- depth look at the workpiece centring systems and the level of cutting quality. Waterjet’s technological answer took the form of the advanced software, devel- oped in-house, which drives the interpo- lation of the axes ±90° and the automatic positioning probing system which can maintain a constant distance between the cutting head and the workpiece in the event of ovalling. The water jet is powered by an energy-efficient Servo 4150 bar hybrid pump: the machine, despite the extra thickness, does not need maximum pressure given that high productivity is not requested.

Listening carefully to the needs of the customer combined with our ability to customise the product has allowed us to develop and tailor machinery with unique features in terms of structure and size

DANIELE PORTOSO

Italy Sales Manager for Waterjet

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires