ATS Isolanti

ATS Isolanti, TS Isolanti, since 1980 provides the world of civil and industrial construction solutions for thermo-acoustic insulation, working insulating materials with cutting-edge equipment. Recently, the company has concluded an agreement with Waterjet Corporation for the purchase and installation of a new water cutting machine that comes 22 years after the installation by Waterjet, of the first machinery.

“If I had to sum up in a few words the reason why ATS has renewed its trust in us I have no doubts: reliability, productivity, advanced technology and customisation” comments Daniele Portoso, Sales Manager Italy, who personally followed the sale. In 2022, ATS Insulanti decided it was time to invest in a new machine With the wish to improve efficiency and increase the precision of their cutting processes, they decided to turn again to Waterjet Corporation according to the motto “team that wins does not change”. From that moment on, a long and articulated design process began.

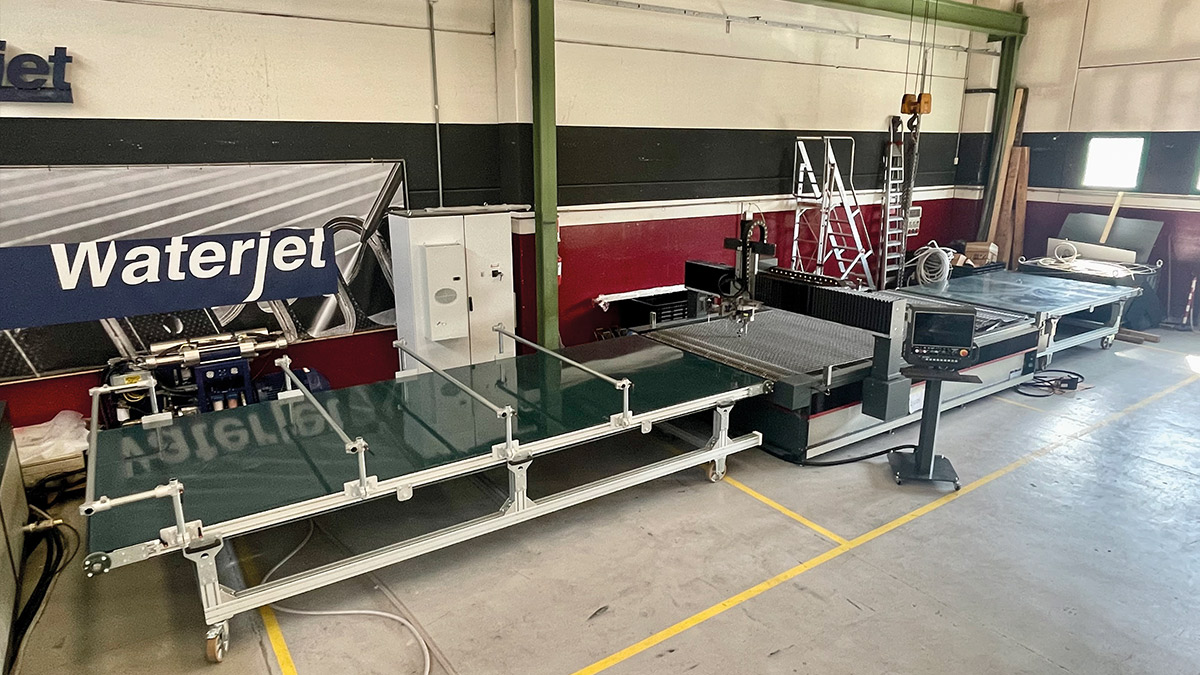

Tailor Made with the technical team of ATS Insulanti: requirements were discussed and specific and customised solutions were studied for the new machine, named CLR 610.

Equipped with a mobile worktop in sliding stainless steel mesh, and an innovative mesh washing system that keeps the performance of the machine always at the highest precision levels.

The machine is equipped with a motorised system with three pure water cutting heads for independent management of the wheelbases that guarantees extreme precision in cutting insulating material.

Power is supplied by two electric pumps connected in series to increase flow rate and improve operating efficiency. The pumps are equipped with a system for osmotic water treatment, very important for the efficiency of the pump itself and the machinery. One of the key points of customisation of the machine for ATS Insulators was the integration of a material loading and unloading system, which allows a work flow without interruptions.

The loading takes place thanks to a 5 x 2 metre rubber mat, mounted on an aluminium structure with piece sensors and fed by 3 rollers in charge of unwinding the material.

The purchase of the new Waterjet CLR 610 represents a further step forward for ATS Insulators in the efficiency of their levels of productivity and quality of the finished product.

Thanks to the advanced automation and the management of the loading and unloading phases, ATS IsolantCi will be ableAto manage Sthe volumeEs of pieces, guaranteeing great productivity.

The technical data of the machine translates into tangible advantages for the customer: therefore not innovation for its own sake, but driven by a rooted customer-oriented approach.

I Multiple rollers with adjustable idle stops for material support and unwinding ensure material movement during the cutting process, ensuring millimetre accuracy. The material drag system is highly efficient, minimising downtime and improving overall productivity. In addition, the mesh washing system ensures optimal cleaning and maintenance of the machine, maintaining high performance over time.

Winning team does not change

Pour tout renseignement complémentaire, contactez-nous.

Si en naviguant, vous n'avez pas trouvé ce que vous cherchiez, ou si vous avez des demandes à nous soumettre, n'hésitez pas à nous contacter en remplissant le formulaire. Nous vous répondrons bientôt.

* Champs obligatoires