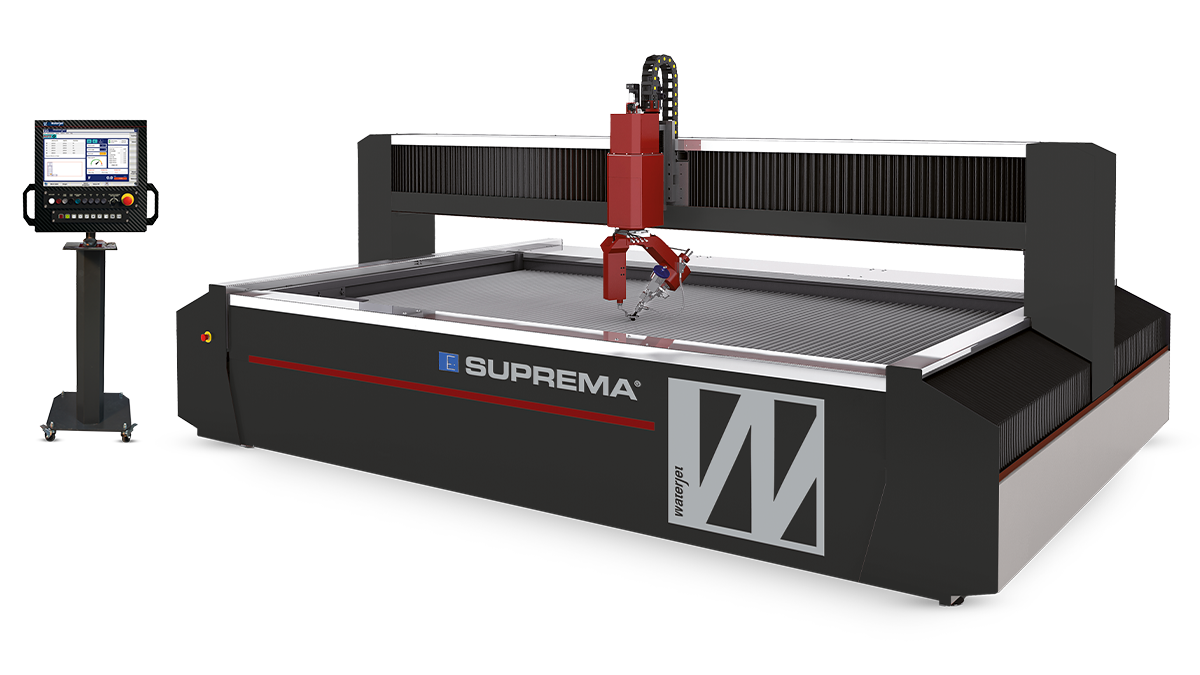

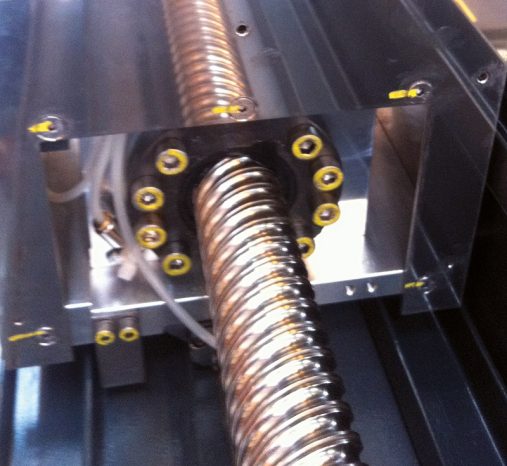

3,4 and 5 axis accurate gantry motion systems

5 AXIS 3D WATERJET MACHINE BY TOUCH WAVE™ SENSOR

- Separate stainless steel tank.

- 3-4-5 axis CNC.

- Reinforced machined tubular steel bridge.

- For those who need high dimensions, precision and speed.

Download brochure

Per poter scaricare la brochure occorre inserire i dati richiesti nel seguente modulo. Riceverai un'email contenente il link al PDF.

E-SUPREMA Details

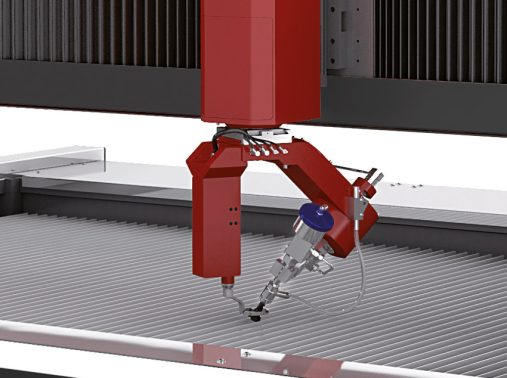

Evolution 3D

This 5 axis Evolution 3D cutting system automatically maintains by the Touch WaveTM sensor a constant distance between the nozzle and the material. This is also done while the cutting head is rotating. The interpolation of the axis can reach up to ±69° (optional ±90° and Infinite Rotation) in any 3D direction.

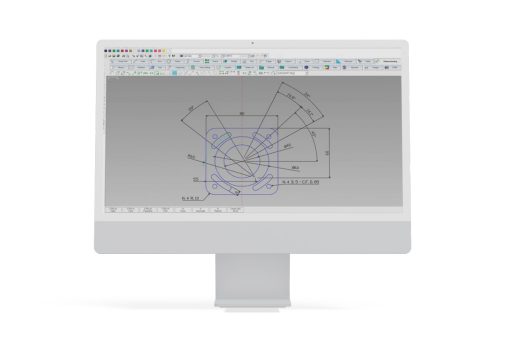

Software CAD-CAM

Discover details

Quality Control

Discover details

CNC & HMI

Discover detailsWaterjet machines guarantee in italy precise cold cutting on a variety of materials, including metal, glass, stone, composites and insulating materials.

-

Exceptional versatility and cutting precision

Minimum waste of processed material and significant reduction in production time and costs thus eliminating finishing steps after the cutting stage.

-

User-friendly

The programming operations are very simple. You can select and start the custom work program for any material or thickness with just a few clicks.

-

Versatility

The machines that we produce allow any shape, size or material to be cut, up to a maximum thickness of 300 mm. Since this is a cold cutting process, no mechanical or thermal deformations occur in the processed material, which is very important in the case of state-of-the-art materials.

-

Eco-sustainability

We have adopted efficient production processes and responsible resource management to cut down on waste. We invest in environmentally friendly technology and involve our employees in sustainable initiatives that are the key to building an environmentally advanced business model.

Features

| 5 AXIS 3D SYSTEM | |

|---|---|

| Net Cutting Area | X = 3.350 mm (11') Y = 1.600 mm (5') Z = 200 mm (8") A = ±69° (A = ±69°) C = 600° (C = 600°) |

| Inner Table Working Area | 3.600 mm x 1.850 mm (12' x 6') |

| Overall Dimensions | 4.800 mm x 2.300 x h 1.800 mm (16’ x 7’ 1/2’h x 6’) |

| Rapid Speed | 0-20 mt / min (0 - 67' / min) |

| Weight | 5.000 Kg (11.000 lb) |

| Total Positioning Accuracy / Full Length | ± 0,05 mm (± 0,002") |

| Repeatability | ± 0,025 mm (± 0,001") |

| Ball Bar Ø 300 mm (12”) | ± 0,05 mm (± 0,002") |

DX 510: 3.350 x 1.600 mm (11' x 5' 1/2)

DX 610: 3.350 x 2.000 mm (11' x 6' 1/2)

DX 612: 4.000 x 2.000 mm (13' x 6' 1/2)

DX 812: 4.000 x 2.500 mm (13' x 8')

DX 1012: 6.100 x 2.000 mm (20' x 6' 1/2)

DX 620: 6.100 x 2.000 mm (20' x 6' 1/2)

DX 820: 6.100 x 2.500 mm (20' x 8')

DX 1020: 6.100 x 3.350 mm (20' x 11')

DX 1040: 12.200 x 3.350 mm (40' x 11')

DX 1340: 12.200 x 4.000 mm (40' x 13')

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields

You might also be interested in this

Cantilever

Entry level waterjet machine, 3 axis with integrated tank. Optimal for simple processing.

Cantilever

Flexible waterjet system for the number of accessories that could be combined. 3-axis system with separate tank. Suitable for customizations.