Waterstone WA 110 puts its productivity at Caicedo Stone’s service

Caicedo Stone, a Spanish company, established in 2003, is a service company specialised in natural stone, marble and granite processing, that promises to its customers the highest level of processing quality and excellent response times, all thanks to its impressive and groundbreaking company infrastructure.

Waterstone WS 110 is the latest machine purchased by Caicedo, allowing the Spanish company to complete its range of provided services by adding the Hydrofinish waterbased surface treatment to all the surface treatments already offered by the company such as resin coating, flaming, and bush hammering.

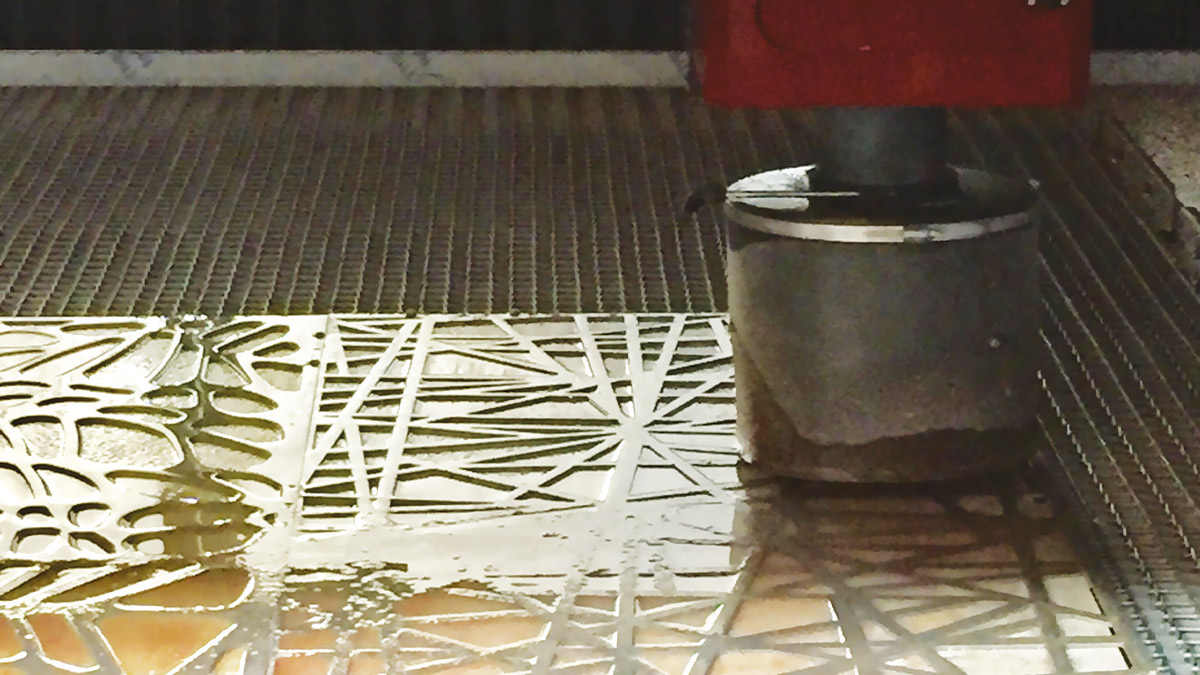

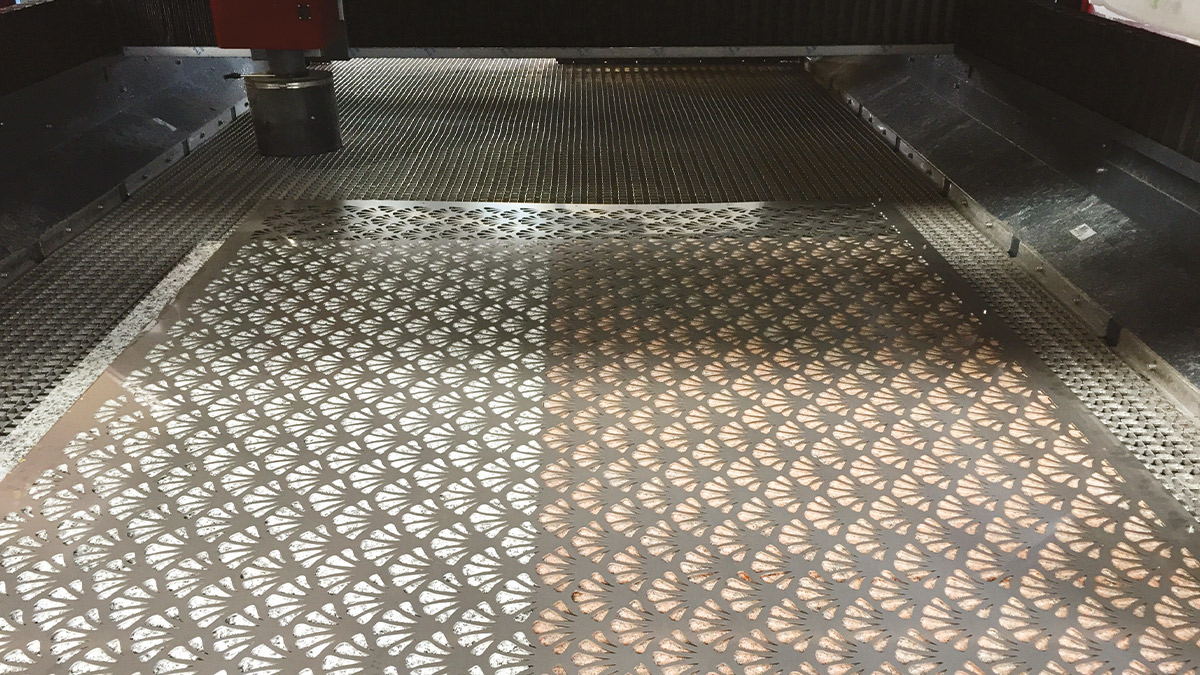

“To meet the latest architectural trends, Caicedo wanted to provide itself with a machine that would enable the company to decorate the processed slabs with geometric contrast effects like striping. This particular kind of processing can be obtained only by means of a machine equipped with a multi-nozzle head, like our Waterstone WS 110”, explains eng. Massimo Russo who, after the first contact with Caicedo at the Marmomac trade show, has personally supervised the machine sale, and subsequently its installation and trial.

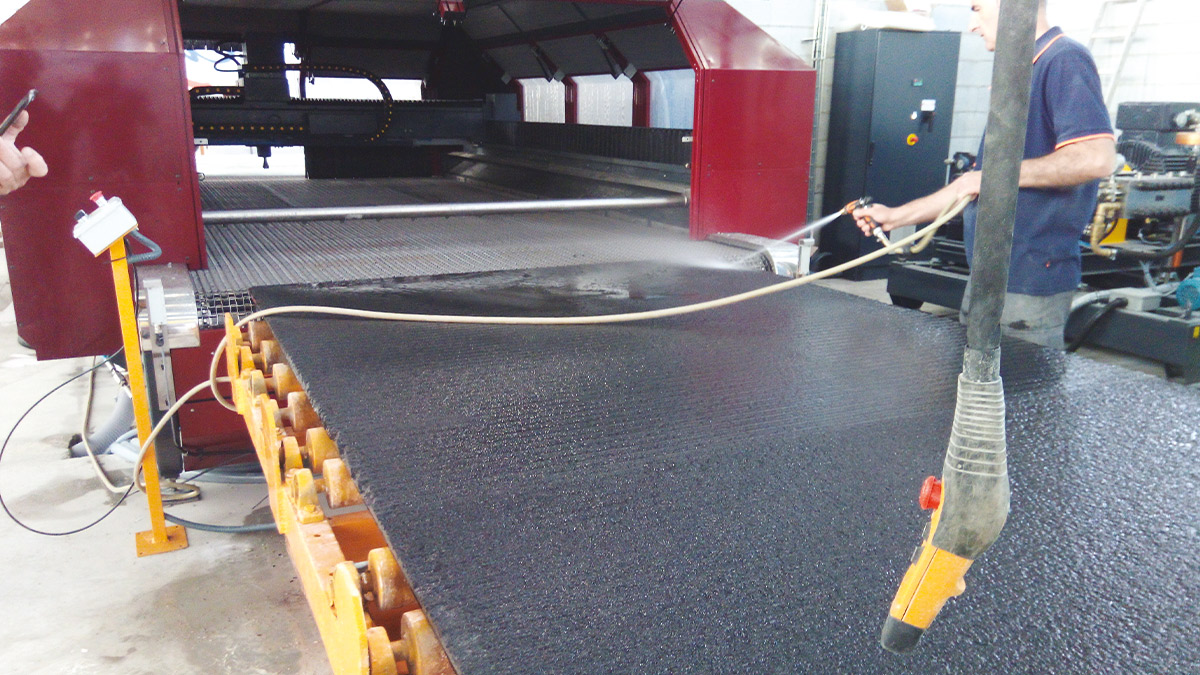

This very-high productivity decorative hydro-finishing processing line is fully automatic and equipped with a system designed to load and unload the slabs, handled across the processing area through a conveyor belt. Thanks to its 110 KW hydraulic intensifier, able to emit 28 litres of water per minute, the machine ensures a production cycle of 30-50 Sq m per hour.

Caicedo Stone is a company renowned for the quality of its raw materials, and Waterjet Hydrofinish technology exalts the aesthetic potential of natural stone while protecting its every shade of colour. A rotating head with multiple orifices generates a high-pressure water brush effect that works the surface and, according to parameters such as pressure, the amplitude of the radius and the distance of the jet, it generates a kaleidoscope of plastic and chromatic effects. As in the cutting process, the Hydrofinish system is an entirely environmentally sustainable industrial process, since it does not produce smoke, heat or polluting liquid waste.

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields