The perfect synthesis between technology and creativity

Within the vast landscape of secondary processes dedicated to glass, shape cutting is one of the most complex. Water cutting technology is the ideal solution for shaping complex glass profiles, as it can also be used to drill and engrave any thickness of glass with high precision, while maintaining the chemical and physical characteristics unchanged, since it is a cold technology.

Arte Veneziana, a distinguished brand operating in the bespoke production of furniture and furnishings with a high artistic value, has chosen Waterjet Corporation to acquire this highly versatile technology.

The creative potential that a Waterjet machine provides Arte Veneziana operators with is very high. In a field of application such as furnishings, where creativity and ‘craftsmanship’ quality are the conditions that production is based on, having in-house Waterjet technology, which automates the shaping and finishing process of geometrically complex profiles (and therefore, impossible for a regular automatic CNC cutting table), significantly reduces the implementation time of an object and increases control of these process phases, which would otherwise be carried out manually or even outsourced. The medium-term cost-benefit ratio of the investment can only have a positive effect.

Giancarlo Zanin founded Arte Veneziana in 1983 based on the business he already ran way back in 1971, producing Venetian mirrors, and today looks to the future of the company led by his sons, Alessandro and Nicola.

Arte Veneziana befits the path paved by the Venetian engraving tradition: the mission is to go ahead and develop this tradition through a constant search for excellence, obtained through rigorous work that is constantly in line with the latest methods and technologies. Glass is the soul of furnishings, lights and accessories that combine artisan manufacturing traditions rooted in the past with the search for decorative applications and contemporary approaches.

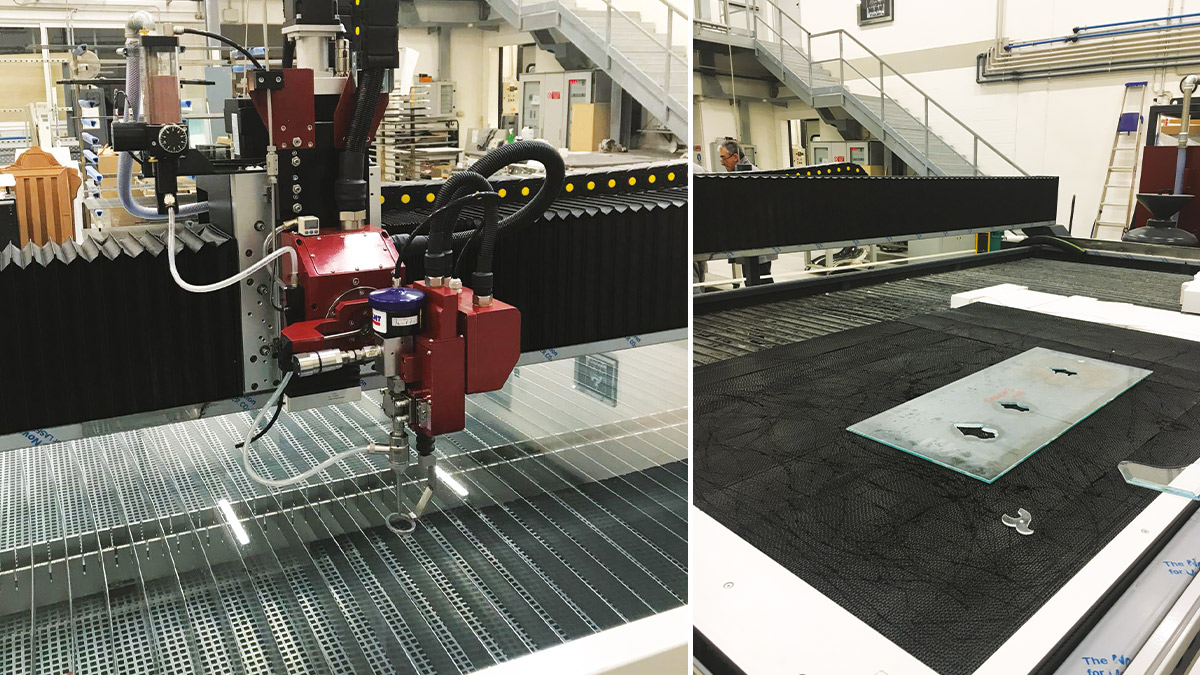

Waterjet Corporation has installed a 5-axis Classic CL510 Waterjet machine inside the Olmo production centre in Martellago, near Venice. The facility has been customised with a honeycomb worktop that prevents the contact of the glass pieces with the metal structures of the tank. A propeller is installed on the cutting head, suitable for 120 Mesh abrasive powders: the perfect granulometry for glass cutting. With the same machine, Arte Veneziana can also cut other materials that are used for their creations. The machine is also equipped with an automatic sludge evacuation system which, by automating the process, prevents the extended machine downtime imposed by manual execution.

The use of water cutting technology, which is completely eco-friendly, is in line with the environmental approach promoted by Arte Veneziana: safeguarding the local area is the basis of the business of a company constantly engaged in analysing and monitoring production to reduce the polluting impact.

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields