Pinacar

Pinacar is a leading company on the Spanish stone and ceramic scene which boasts a state-of-the-art production infrastructure: the highest quality standards required by customers oblige the company to adopt the best technologies to carry out even the most refined processes, achieving quality excellence.

Daniele Portoso, Commercial Manager of Waterjet Corporation, says: “I met the customer in Verona, during the 2018 edition of Marmomac. We immediately impressed the client positively, thanks to a few demos that paved the way for our relationship. After my visit to their factories in Tomelloso, in the centre of Spain, the deal was almost complete. We finalised the details and went into production. 3 months later the machine was already installed at the customer’s premises”.

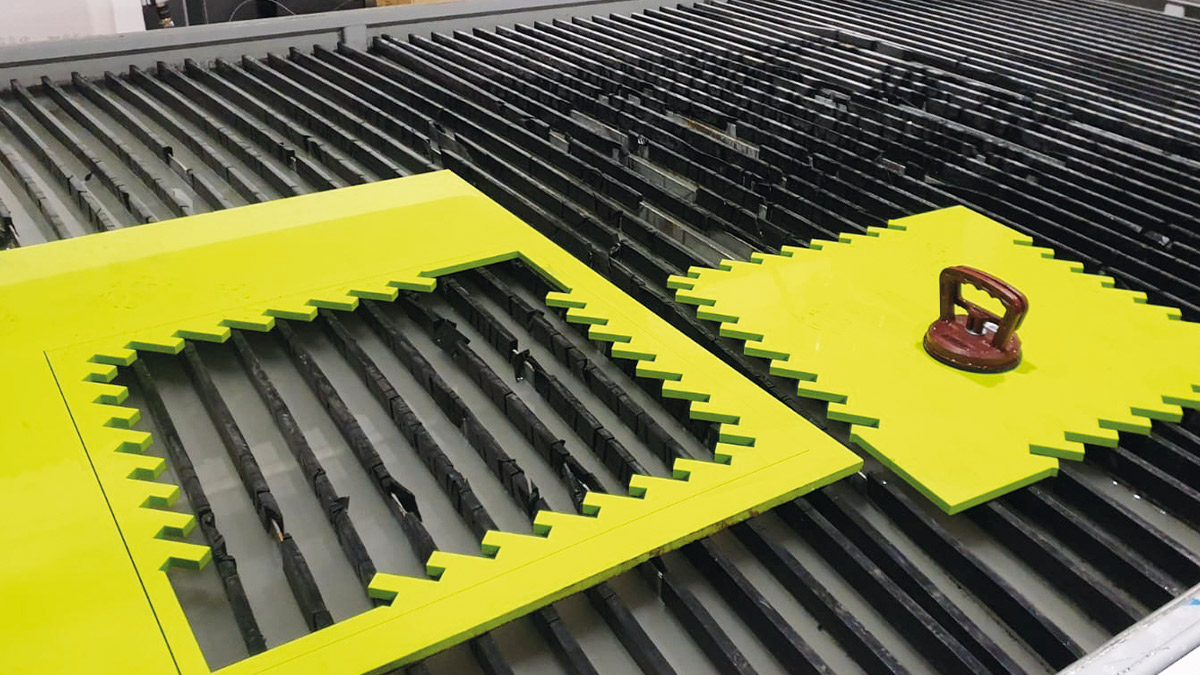

A Classica 612 model, with 4000×2000 work surface, equipped with a 50 horsepower intensifier pump. The machine has an X3 Evolution 3D cutting system with 5 interpolating axes with infinite rotation for cutting in space at ± 69°; this guarantees the space cutting of complex shapes and a high productivity in 45° plate cutting.

The machine is equipped with a digital camera driven by a software that allows automatically loading images or geometries which are then imported into the cad system: this function enables the operator to generate the different cutting programs with just a few clicks. The camera also detects any discrepancies on the slab and the “plate” function guides the operator in selecting the best area for cutting the piece to optimise production.

The machine is equipped with the pre-probing system which protects the precision of the machined pieces. Thanks to a feeler mounted on the cutting head, which mechanically detects the deviation of the thickness of the plate, this technology automatically corrects the cutting trajectories on the Z axis based on the direction of the plate surface which, especially in the case of non-flat or even corrugated ceramic slabs – as is sometimes the case with thinner materials – is very often

not uniform. The system continuously detects the actual height of the slab and automatically corrects the cutting trajectories, obtaining perfect plates every time, which will require minimal adjustments during the gluing phase: the result of the cut is, in fact, practically perfect. In this way, a finishing operation after the inclined cutting of the profile will not be required to assemble two slabs.

Quality, flexibility and productivity: these three aspects condense the Pinacar job order.

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields