Castle Metals

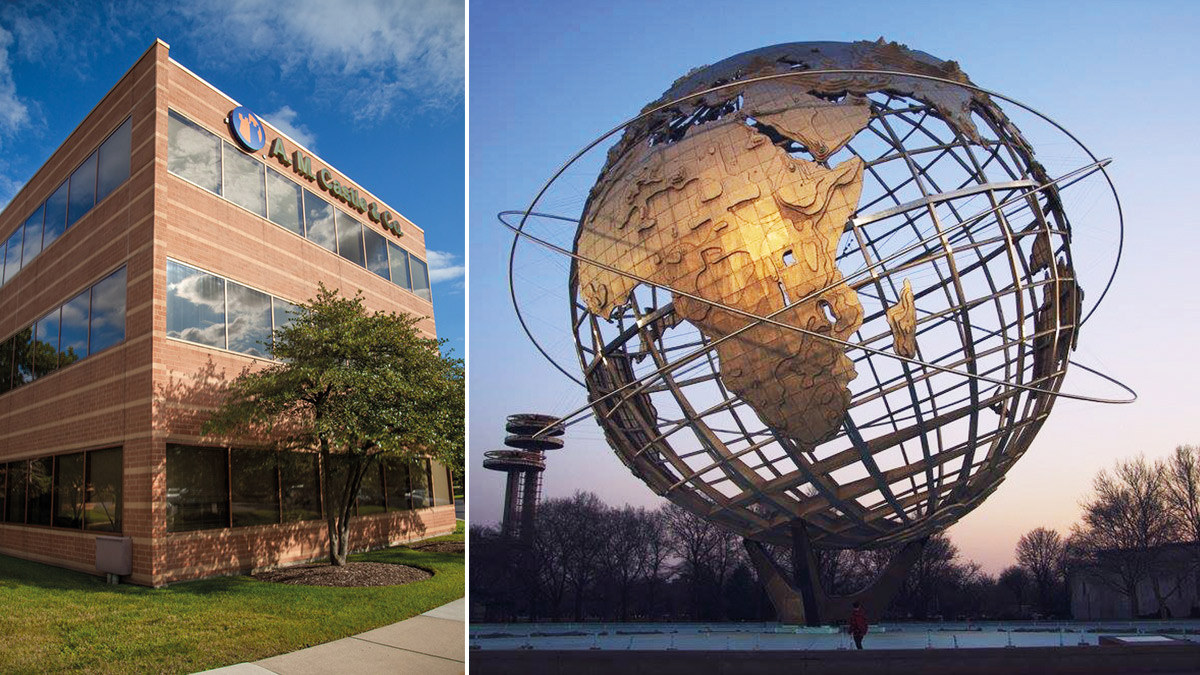

Castle Metals is a leading international company in the iron and steel industry. It produces and processes a wide range of steel, carbon, stainless steel, nickel, aluminium, titanium, cast iron alloys and other metals.

One of the core businesses of the iron and steel group is dedicated to the aerospace sector where, recently, there has been a consolidation in the trend to purchase semi-finished parts and no longer raw material to be processed internally. This change of direction in purchasing decisions is closely linked to fluctuations in the alloy markets. In order to be competitive on the market, customers operating in the aerospace sector cannot store large stocks of materials as a result of major investments, but must stock up just in time with semi-finished parts to be used for subsequent final processing and assembly.

To cope with this trend in demand, Castle Metals has equipped itself with high-end Waterjet systems, in order to process the pieces intended for the aerospace sector without running the risk of chemical and/or physical deformation of the piece. The aerospace sector is characterised, in fact, by strict qualitative specifications of the order as well as by very high request rates, at least up to the forced stop following the recent Covid-19 epidemic.

Therefore, Castle Metals was looking for plants that could ensure reliability, productivity, and processing quality, avoiding the risk of compromising the pieces: to meet this request, Waterjet Corporation, in competition with other players in the sector, supplied, through an international agreement, Castle Metals with three water cutting plants equipped with 6,200 bar KMT PRO intensifier pumps, 5-axis technology and multiple heads to quadruple their productivity.

The machines that have been installed in the production sites in Texas, California and France are required to process large parts up to 4m x 12m with thicknesses up to 250 mm. As evidence of the value introduced into Castle Metals by Waterjet technology, the request from the French site for a 4th machine which arrived shortly afterwards, to meet an ever-increasing number of requests.

The productivity and reliability of the Waterjet technology is clearly the protagonist of this order because the large thicknesses and large surfaces which have to be cut require continuous work cycles that put a strain on the machine, generating stresses which do not stop sometimes even for days. It is clear that such machines can only be supplied by a technological partner with deep-rooted experience, competence and reliability such as Waterjet Corporation, which has been doing this job for thirty years now, researching and developing the best performing solutions possible for its customers.

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields