The highest customisation standards

Blades Technology Ltd was founded in 1968 by Stef Wertheimer to provide spare parts to the Israeli aviation. In 2014 the company was acquired entirely by the US jet engine manufacturer Pratt & Whitney. Blades Technology Ltd is today a multinational company that manufactures blades for compressors and turbines for engines for three key reference sectors: the aerospace, hydraulic and orthopaedic-medical industry.

Since its foundation, the choices that have oriented industrial policies dedicated to production technologies have always been guided by three fundamental strategic drivers: innovation, ultra versatility and continuous improvement.

These drivers outline the identikit of Waterjet Corporation as an absolute partner for the provision of jet water cutting systems. This cutting technology is indeed necessary to overcome the problems of thermal and mechanical alteration, which are unacceptable in the reference application sectors of Blades Technology Ltd., where very high profile precision is required.

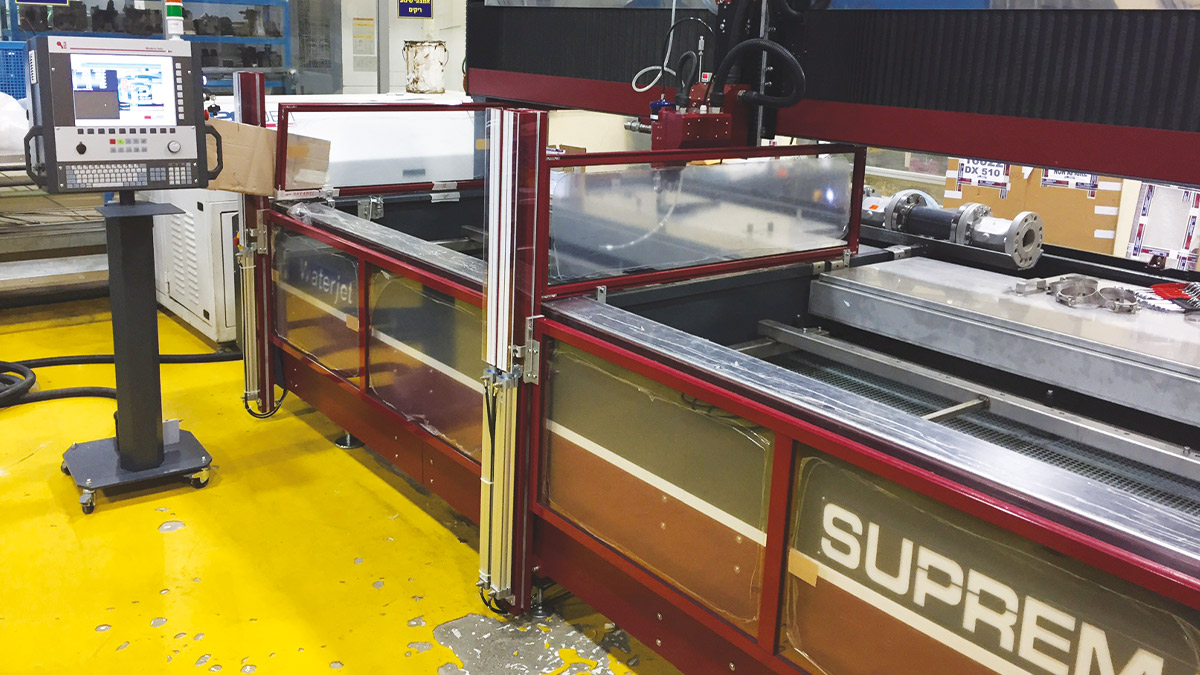

The on-site activity of Waterjet’s extensive sales network has laid the foundations for shorter distances between the supplier and client: the technological excellence of the machines and the high potential for customisation that guarantee the best performance available on the market have done the rest. The sale and installation of the second plant took place recently and represents a milestone in the consolidation of this prestigious partnership. The sale was finalised directly by Mr. Massimo Russo, Vice President, and enhanced the degree of customisation of the supply, which highlights the attention that Waterjet pays to the client’s production requirements.

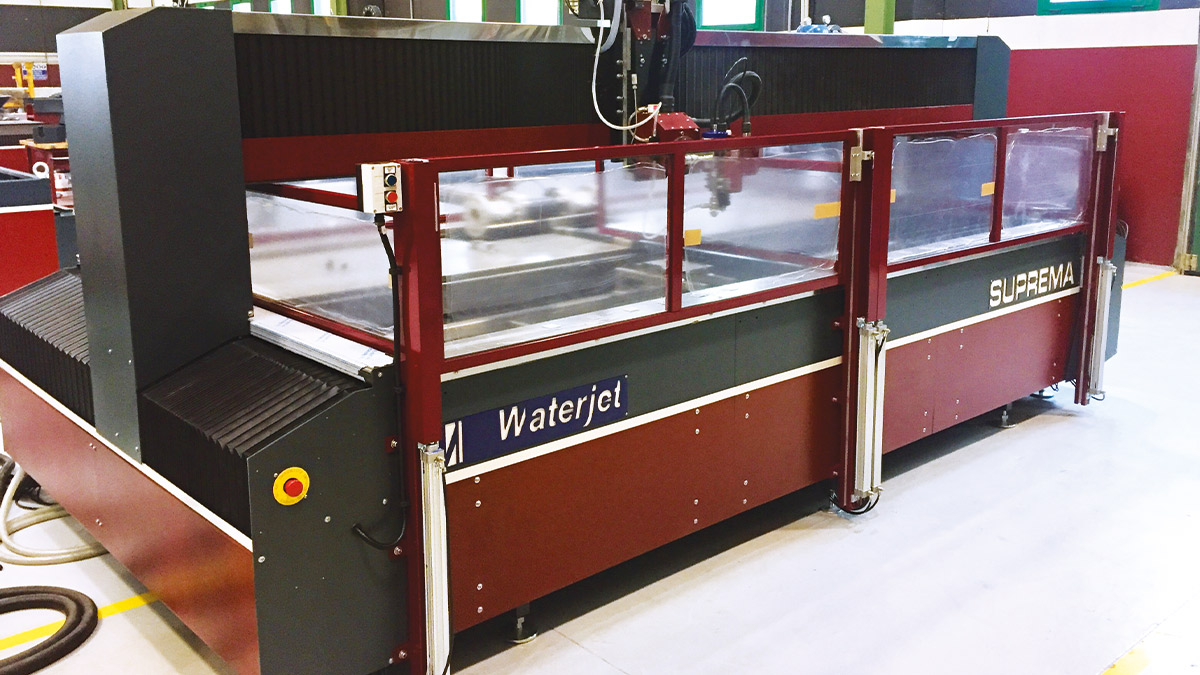

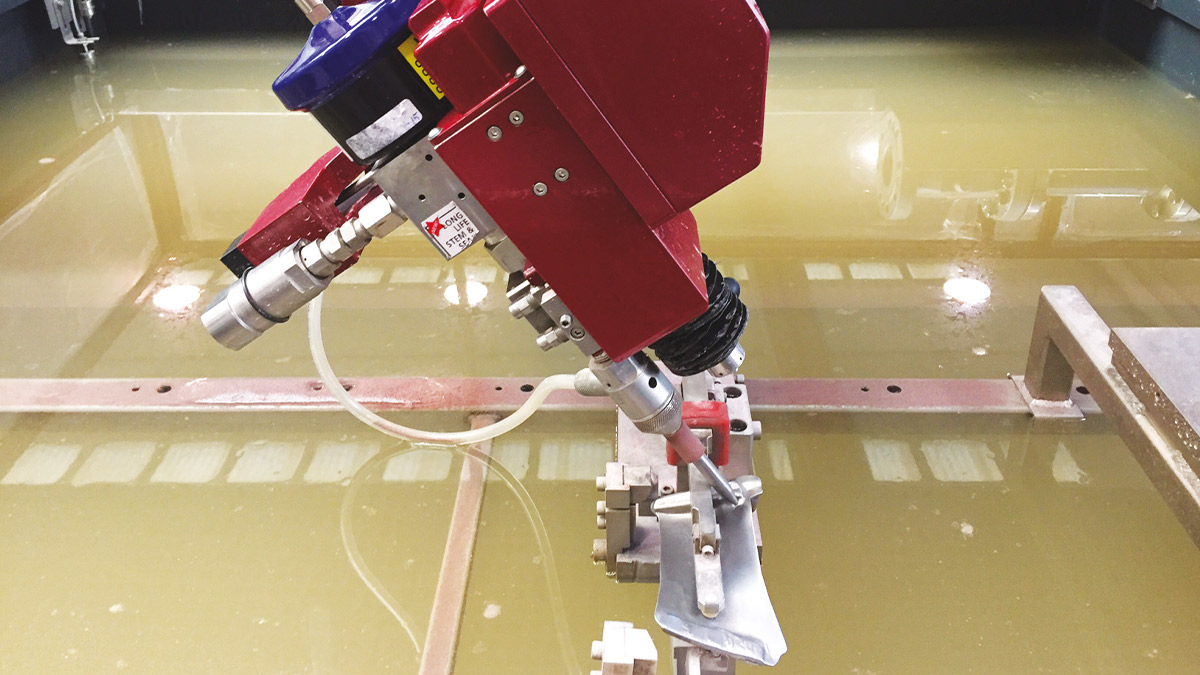

“We have designed and manufactured a highly customised machine for Blades Technology, based on the specific needs of the client: the Suprema DX 510, a high precision machining centre with a 5-axis 3D head with probe, and laser pointer with two distinct work areas. The two areas are intended to cut and the other to load and unload special templates on which the pieces are positioned to be processed. The customisation of the cutting programs stored in the management software, with which the machine is equipped, allows the client to significantly reduce production times: by simply selecting the cutting program, the work centre does the rest.”

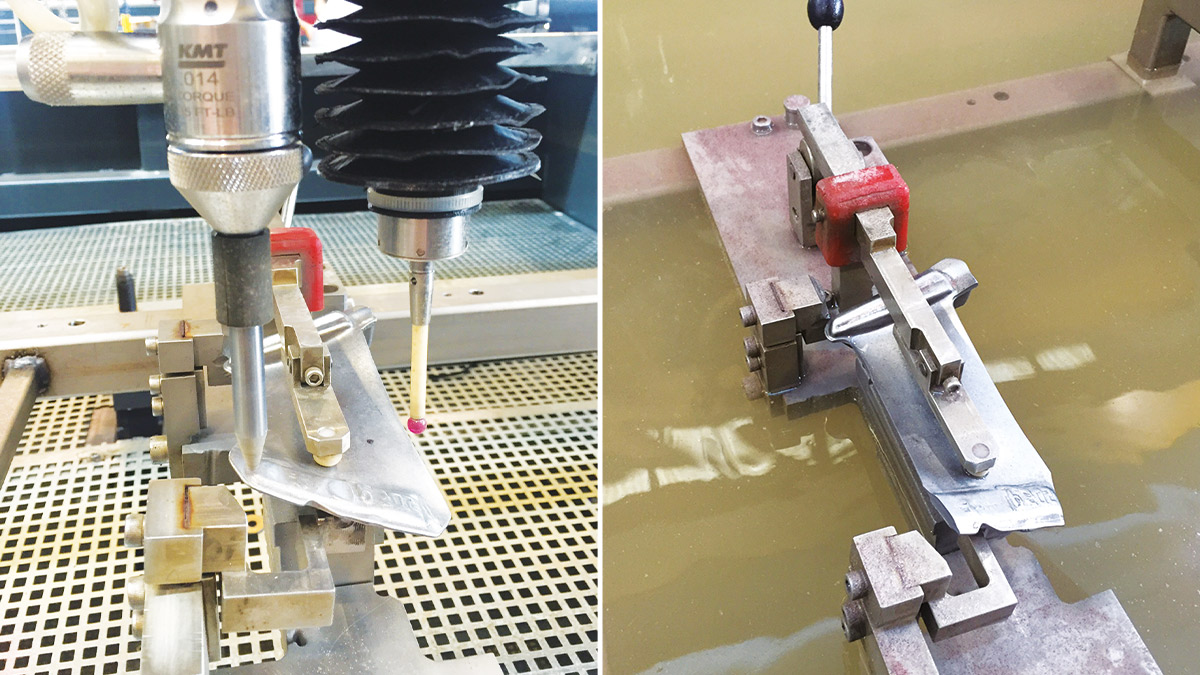

In order to guarantee extreme processing precision and a tolerance below five hundredths, a precision probe is installed on the machine that perfectly identifies the positioning in the workpiece space: based on the information transmitted by the pointer, the NC loads the cutting program and proceeds with the processing.

Before relying on Waterjet Corporation to automate and optimise this phase of the production process, Blades Technology Ltd would finish products manually with old-generation waterjet machines. The results in terms of tolerance were unacceptable for the sectors the finished product was intended for: this obliged the company to envisage a further finishing phase completed by hand with a consequent negative impact on production times.

“Blades Technology is an American-oriented industrial company. Our partnership with KMT, a US world leading company in the provision of jet water cutting equipment, has supported the client’s choice that has already been handled by Waterjet corporation thanks to the excellent performance in terms of tolerance and repeatability of the cut guaranteed by our machines,” says Massimo Russo.

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields