Al Hasheem meets Waterjet Suprema with Hydrofinish

Al Hashem Marble was founded in Abu Dhabi in 1970: production was initially limited to concrete and ceramic tiles and in 1985 it was entirely converted to the production of marble and granite flooring and cladding. Today, Al Hashem Marble is the undisputed leader in the UAE market for the supply and installation of natural and reconstituted stones and mosaics with a production of more than 200,000 m2/year. The operations have recently expanded to manage large-scale projects in other countries of the Gulf Cooperation Council – the international organisation of the six Arab states in the Persian Gulf – and in the United States.

Through the best technologies available on the market, the company provides an irreplaceable service and productive support to its clients to translate the most ambitious projects into reality: Waterjet technology is an integral part of the production output of the Middle Eastern giant.

“The relationship with Al Hashem Marble has been consolidated for twenty years. We installed the first Classic CL 510 Waterjet in 1998: now, six machines are in production in the facility. The Middle East is a market where we have installed more than three hundred machines, but Al Hashem Marble is a fundamental element in all this: the vision of this client is always been pioneering. They were the first in the Middle East to have the Waterjet technology”, explains Massimo Russo, who follows this market with special attention.

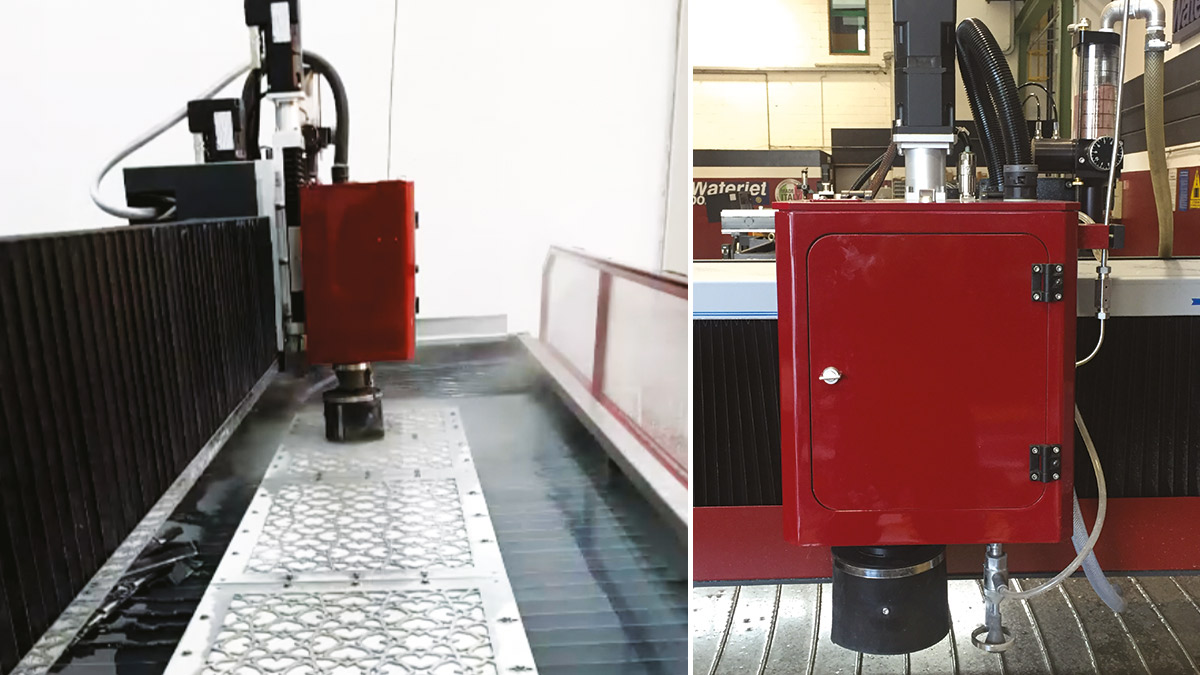

The installation of the new Suprema DX, a top-of-the-range machine, fulfils this pioneering vision precisely to a tee: an actual machine tool that can guarantee cutting precision within 5 hundredths to which a second head was added to the portal for the hydro-finish that allows the operator to switch to fully automatic mode from the cutting head to the superficial finish head.

“The creative potential of Hydrofinish applied to the stone industry is very high and, once proposed to the client, the path towards finalising the order was short and straightforward. Obviously, the trust gained over the years has been a solid basis for the negotiation,” says Mr. Russo.

Waterjet’s innovative Hydrofinish technology exalts the aesthetic potential of natural stone, while protecting its every shade of colour: a rotating head with multiple orifices generates a high pressure water brush effect that works the surface and, according to parameters, such as pressure, amplitude of the radius and distance of the jet, it generates a kaleidoscope of plastic and chromatic effects. The superficial treatment can be homogeneous or geometric by using pre-cut steel templates that are applied on the surface as a sort of frame for silk-screen printing. The template is made by cutting steel slabs with the same water jet: the machine is thus fully autonomous. This last type of processing is suitable for claddings and wallpaper effect stone according to the latest trends of contemporary architecture.

According to Mr. Russo, “Waterjet has an innate innovative nature that is always ready to respond proactively to productive-creative requirements, even before they emerge from the various industrial sectors where water cutting is applied: in our factories we innovate every day, always paying utmost attention to international markets in order to seize every opportunity and anticipate trends”.

Wenn Sie Informationen wünschen, nehmen Sie bitte Kontakt mit uns auf.

Wenn Sie beim Stöbern nicht gefunden haben, was Sie suchen, oder wenn Sie Fragen haben, zögern Sie bitte nicht, uns über das Formular zu kontaktieren. Wir werden uns in Kürze mit Ihnen in Verbindung setzen.

* Pflichtfelder