Front Street Shipyard

The largest Waterjet machine ever built

A job order concluded in one year, a government investment fund of the state of Maine in the US to finalise the purchase of the machine, a leading shipyard in the US boating industry, the technological excellence of water cutting: these are the elements at the basis of the success story that Waterjet Corporation wishes to narrate in order to convey its ability to provide high-end and highly customised technological solutions.

“When I saw Waterjet’s Suprema in action, all perplexities vanished: I flew to Michigan as Waterjet invited me to see for myself what could be done with a 5-axis cutting head technology, supported by 6,000 bar of power. I immediately understood that we needed that level of technology to work high thicknesses and to be highly effective over the whole range of materials we have to process”.

This is how Craig Picard, lead designer of Front Street Shipyard, an important shipbuilding company in the state of Maine in the USA, comments.

The sale of this plant was handled directly by Waterjet USA: National Sales Manager Scott Mullis oversaw the relationship for the whole of 2020, finalising the order at the end of March.

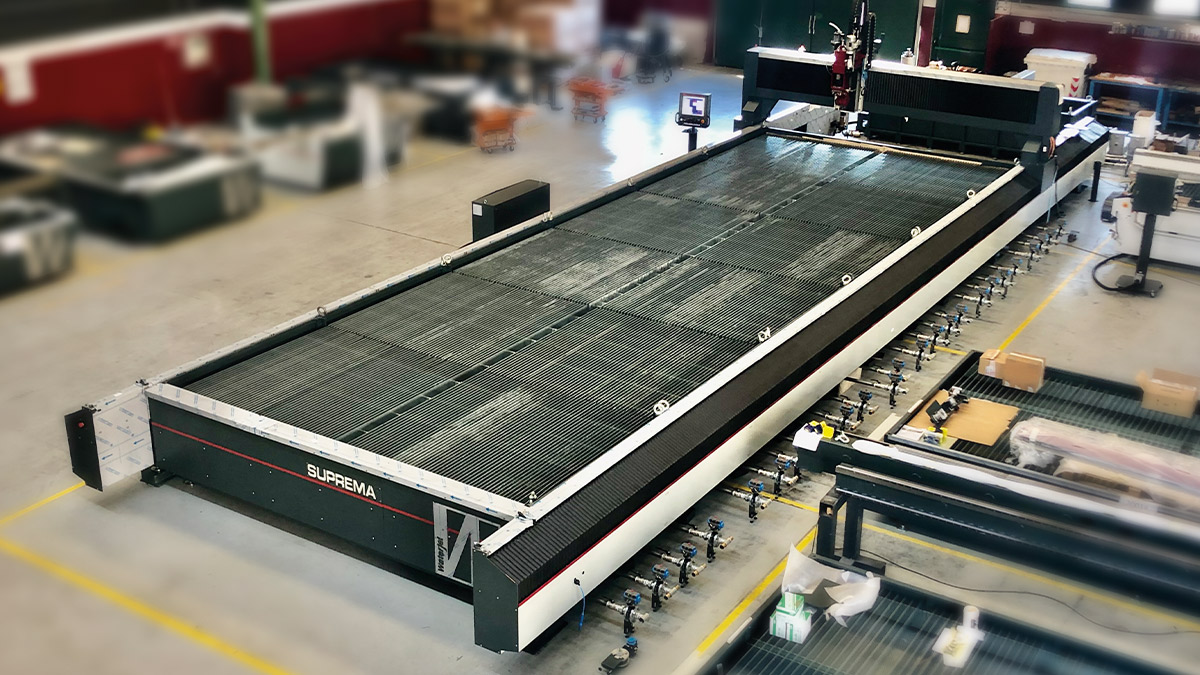

The machine model installed at the shipyard’s manufacturing site is a Suprema DX 1340. This model contains the maximum expression of water cutting technology that the current market can offer: the cutting head works in space by interpolating 5 axes and, to this potential, a sixth working axis is added. The machine, in fact, is integrated with a tank where the lathe cutting of tubular parts is carried out. The machine’s layout envisages two distinct work areas: the 12×4 metre plane on which large surface pieces of metals and composite materials are cut is integrated by a tank where the cutting and caulking of large and thick pipes is carried out. The cutting head moves from one area to another without interfering with the loading/unloading of the machined piece: this allows the operator to prepare and complete the work on one piece while the machine is working on the other. The high power which supports the machine is added to production optimisation: the 6,000 bar pressure of the jet produced by the intensifying pump allows cutting large thicknesses while maintaining unaltered the accuracy and precision of the cut.

Last but not least: the integrated tank for cutting tubular components. Lathe cutting is an extremely complicated application. A large part of the success of this job order probably derives from the fact that no other player on the market is able to produce a 6-axis water cutting technology of tubular components of great thickness and size. The cut to perform the grooves for subsequent welding couplings is an inclined cut in space to which the rotation of the machined piece is added. The rotation is possible thanks to two spindles mounted on the machine with which the tube is keyed. In order to support the two spindles, Waterjet has installed and engineered two movable stainless steel arms on the tank that support the piece and allow releasing the counter-head and proceeding with the cut in the peripheral area of the piece as well.

This is the story of a true technological gem that Waterjet has designed, built and engineered around the specific needs of the customer, once again confirming its ability to provide customised solutions in multiple target sectors and for the most complex production applications.

Wenn Sie Informationen wünschen, nehmen Sie bitte Kontakt mit uns auf.

Wenn Sie beim Stöbern nicht gefunden haben, was Sie suchen, oder wenn Sie Fragen haben, zögern Sie bitte nicht, uns über das Formular zu kontaktieren. Wir werden uns in Kürze mit Ihnen in Verbindung setzen.

* Pflichtfelder