Waterjet Cutting Solutions

A very high-pressure water jet ejected at three times the speed of sound from the cutting head.

Waterjet cutting is a cold cutting process that consequently does not produce any mechanical and thermal deformations on the processed material.

It does not require any additional processing because the surface of the cut contour is perfectly finished, and the process is entirely environmentally sustainable.

Waterjet solutions allow you to cut any shape, size or material up to a maximum thickness of 300 mm. By using the same tool and parameters during most operations, it is possible to easily cut different materials such as marble, granite, glass, ceramic, composite materials, metals, plastic and insulating materials.

Cantilever

Entry level waterjet machine, 3 axis with integrated tank. Optimal for simple processing.

Cantilever

Flexible waterjet system for the number of accessories that could be combined. 3-axis system with separate tank. Suitable for customizations.

Cantilever

Double tank system with revolving bridge. 3-axis system with separate tank. Greater accessibility and customization.

Gantry

3/5 axis Entry level waterjet machine with 3/5 axes with integrated tank, bridge only on the short side.

Gantry

3/5 axis waterjet Classic system with integrated tank and reinforced bridge. Max performance and precision.

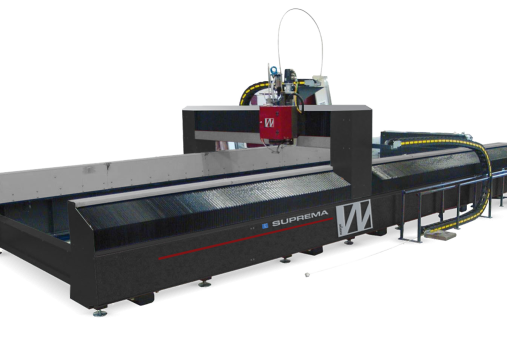

Gantry

Top of the range. Compact waterjet machine with 3/5 axis, high accuracy, separate tank. Ideal for large material dimansions.

Cantilever

High bridge cantilever waterjet cutting system that could be combined with 3/4/5 axes. It meets the processing requirements of different height profiles.

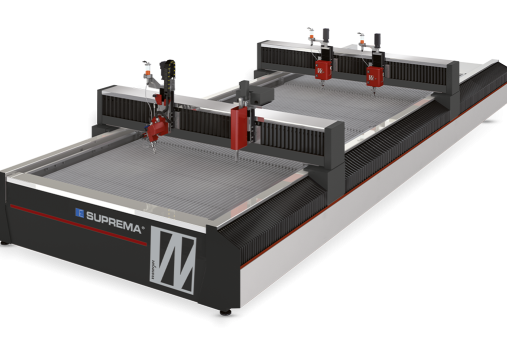

Special

Double gantry bridge waterjet cutting machine, for combinable multitechnology needs.

Special

Engineering and manufacture of standard, special and customized machines suited to the needs of our customers is our…

Special

Combined system of Waterjet & Plasma technologies. High productivity at low cost.